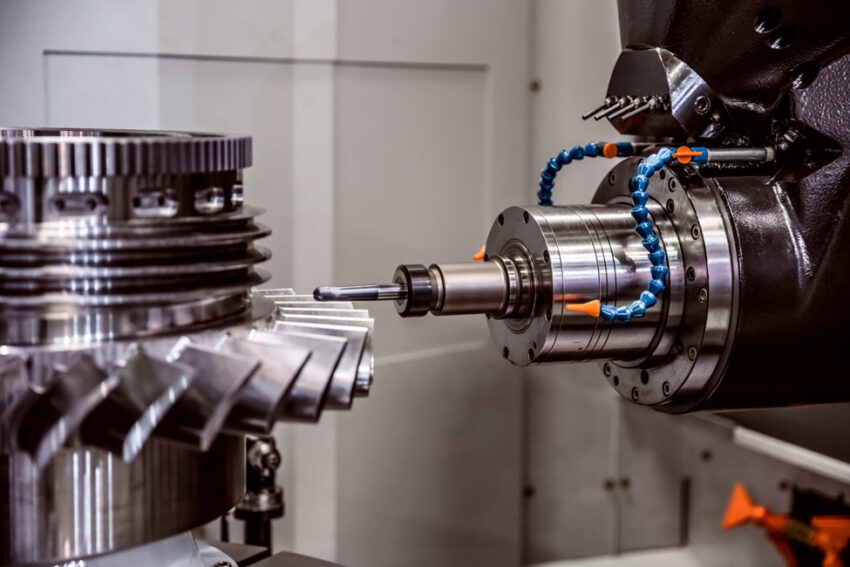

CNC is an abbreviation for Computer Numerical Control, and it works to handle different machines and tools by providing inputs in the computer. These machines or tools involve lathe, grinder, routers, mills, etc. It is beneficial for businesses that involve a high volume of production. Products that are made using these machines are highly precise or accurate.

Sometimes it is confusing for a manufacturer to choose between a new and an old CNC machine. But don’t worry, we have got you covered. In this article, we have shared information regarding this topic to help you choose the right option between the two of them. Let us know some of the factors that can help you decide this.

Factors To Consider While Choosing Between A New Or Old CNC Machine

First of all, know what you want to do with the machine:

The first point that can help you decide on this matter is what you want to create after buying a CNC machine. The new and old versions of the machines will have different options for controlling and customization. It might be possible that an old one uses the old version of the software, but the controller keeps updating it.

Therefore, you need to understand if the particular CNC is solving your purpose or not. If you are looking for more information about computer numerical control machines, then consider checking out elephant-cnc.com.

Consider your budget:

Budget is one of the essential factors you cannot forget to consider while making such a decision. Even if you are searching for some old machine, make sure that it has not been used for a long time. Newer machines generally range from 100000-300000 dollars whereas a used one can range between 70000-90000 dollars. If you go below this price range for buying an old CNC, then the quality of the machine will decrease.

What is the skill level of your workers?

Another factor to note down is the skill set of the employees working under your company. Usually, the latest machines contain software that has a user-friendly interface, making it much easier for them to work on it.

On the other hand, older devices would require you to provide proper training to your workers. Therefore, always consider the skill level of your employees before buying any CNC machine.

Do you require it immediately?

If you cannot accept delays in your work, we suggest you purchase a new CNC because they are much easier to find. At the same time, you may require a lot of time finding an appropriate old machine that can serve your purpose. Thus, time or when exactly you need the device is also an important factor to consider.

To Sum Up

There is no perfect way to determine that one should buy which CNC machine. It all depends upon what exactly you want to do with it and, most importantly, how much you want to spend on it. Apart from these two points, consider the above factors to determine which CNC is suitable for you.