Plastic molding technology is in use since 1972. We have been using this process to create almost every plastic thing that we use. Pay attention to the plastic objects that you use every day. For example, funnels, plastic bottles, handles, buckets and much more. Do you wonder how can someone molds a hard plastic to get the desired shape?

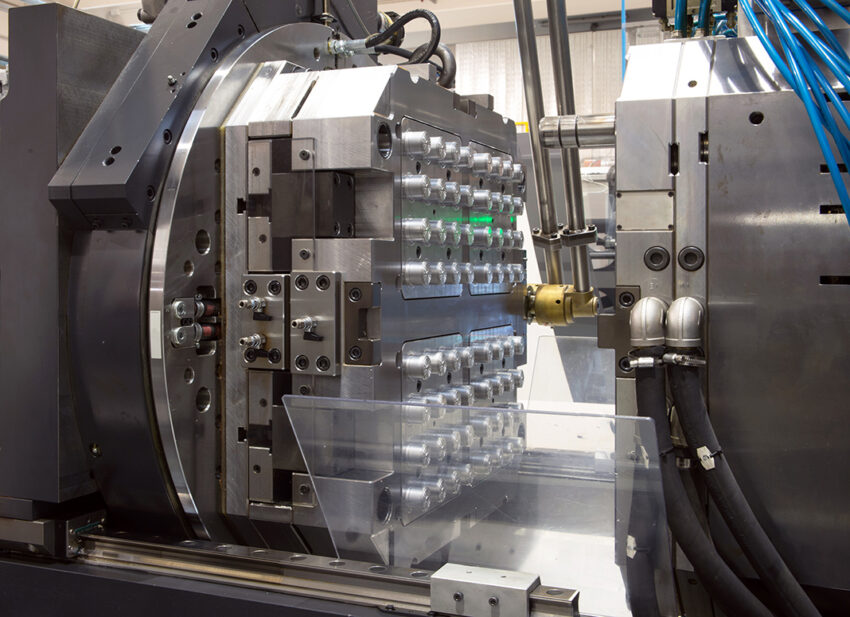

Plastic molding, which is also known as injection molding because of the latest technologies. Instead of pouring molten plastic in the mold, we use injections that inject molten plastic in the mold. This method reduces a lot of mess and waste. In addition to this, it also allows us to make smaller objects that we can use for multiple purposes.

If you are interested in plastic mold, you can go to www.plasticmold.net. You will learn about the history of plastic molding and its use. Furthermore, if you are interested in doing business, you can also check out its future and how can you make molds. In short, you will have the complete process to check out.

1. Micro injection molding

Moving forward in the injection molding technique is micro injection process. And by “micro”, we don’t mean smaller objects in centimeters. Instead, it deals with molds at a microscopic level. This raises a question on their use. Why would we need microscopic level plastics? For medical purposes.

When dealing with medical technology, we need minimum possible exposure to external objects. Furthermore, extreme perfection is also required. Therefore, with the help of micro materials, a high level of precision can be achieved. The smaller the objects, the better precision will be there.

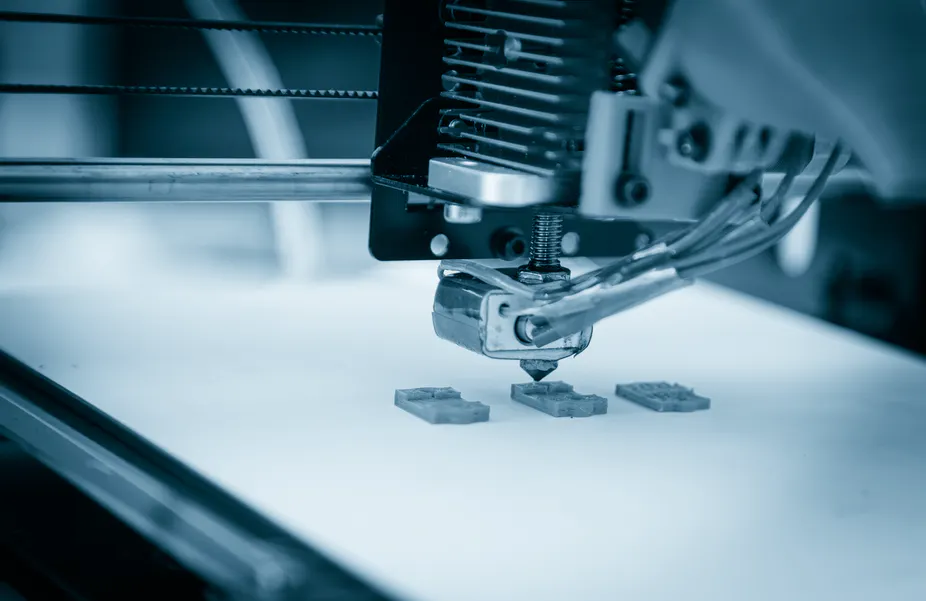

2. 3D printing

3D technology seems interesting and fun but it has a lot of uses in our lives. People believe that 3D printing is all about fun because you can make your toys and action figures. However, if we can use this technology to create toys so why not something useful for the society?

Firstly, this technology allows us to make prototypes from our designs. And because the prototypes are equally functional, we can check out the precision and performance. Thus, it will reduce the expenses of creating expensive machines.

Furthermore, it also allows us to make custom objects to meet the requirements of different industries. The use of 3D printing is also quite beneficial in the medical field. Surgeons can make use of these prototypes to practice their operations and surgical techniques.

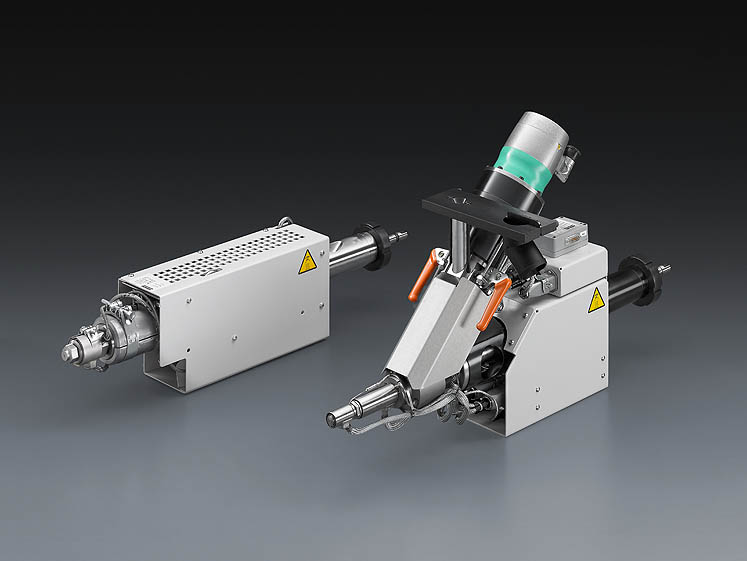

3. Better automation

Automation is increasing in every field and so does the plastic molding. It has reduce the need of humans and thus, the manufacturer will need less workers.

In addition to this, automation in this field can bring enormous change. With less human involvement, we will have less to worry about. Why? Because it will get rid of human errors. Robotic machines can work efficiently and can offer high accuracy. Thus, they can work more than a human worker and with less errors and mistakes.