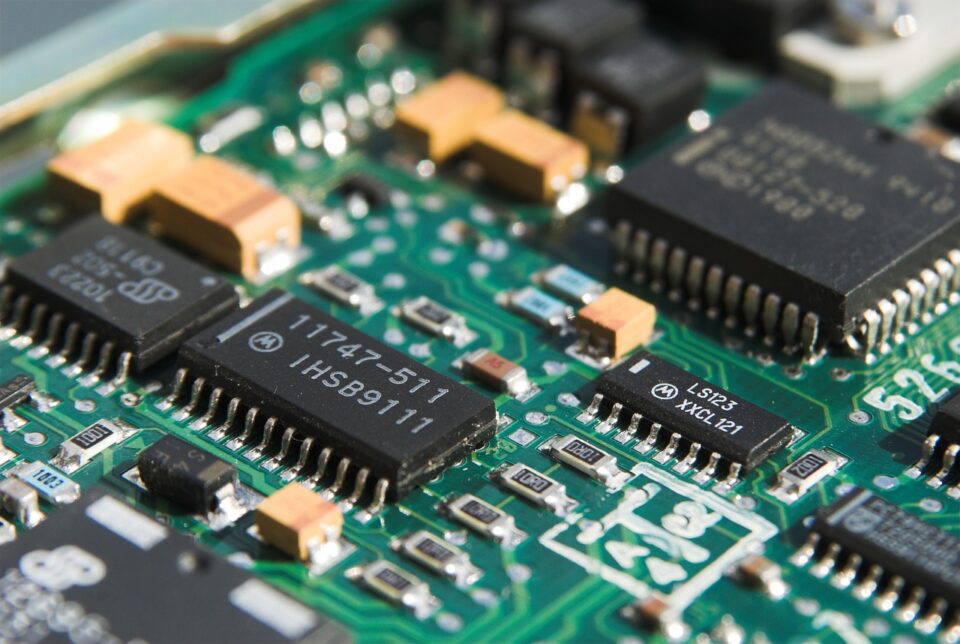

As you surely know, a printed circuit board is an essential part of every device and household appliance. It is what ensures the high quality and long life of a device you have just added to your collection. However, it is critical to use the right materials during the manufacturing process for it to work perfectly.

Now, this is when an issue may arise. If you are currently working on your own project, you need to choose the appropriate PCB material, and here is how to do it.

1. Think about your design

The most important thing you have to do when choosing the materials is to consider your design’s requirements. Printed circuit board consists of four layers, and you have several options when deciding on each of them. For example, FR4 is most commonly used as a substrate, but if you need something a bit more flexible, Kapton is the right choice for you.

2. Conduct research

Once you have a specific list of requirements, it is time to investigate your options. The thing is that there are numerous types of materials, and you need to learn about all of them. Why? Well, each material has a specific set of features. Naturally, it is vital you can benefit from these because otherwise, your new design and device won’t be very effective.

3. Go with available parts

We understand how confusing this may sound, but hear us out. When building a device from scratch, you want to make it almost perfect, so you use the best parts and components. When conducting research on what these are, you may come across information that some of these are hard to get. Your first instinct would probably be to order the parts and wait for them to be delivered for as long as necessary.

Nevertheless, what happens when the component fails, and you cannot use the device until you get a new one? Yes, this is an issue, so it is always advised to go with widely available parts you can order and purchase easily, and you can inspect them on uetpcba.com.

4. Consider safety

Now, depending on the type of project you are working on, safety can be a major concern. Still, it doesn’t mean you shouldn’t think about it when going through the process of selecting materials. You need to learn how each component of the PCB acts and choose the material accordingly. For example, solder may exhaust toxic fumes, so it needs to be enclosed. These toxic fumes cannot be released into the atmosphere and therefore need to be cleaned. So, if this is a challenge you face, you may think about changing the solder and wires with water-soluble, electrically conductive molded plastic.

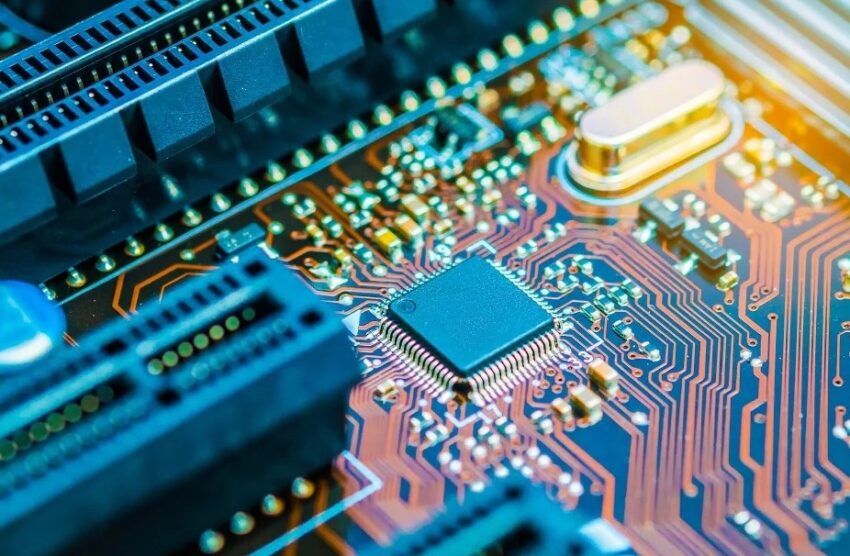

5. Thermal consideration

Finally, you need to think about the heat the device will produce since you cannot eliminate it. If you go with a material that doesn’t have the right thermal conductivity, the chances are your device won’t last very long. Due to this reason, you need to calculate the amount of heat that will be emitted and choose materials that can support it.