In the world of fashion and apparel, T-shirts have carved out a ubiquitous niche, serving as canvases for personal expression, brand identity, and artistic creativity. For businesses, T-shirt printing presents an enticing avenue for promoting products and fostering brand recognition. However, in an era where cost-efficiency is paramount, mastering the art of budget-savvy T-shirt printing is crucial. In this comprehensive guide, we will explore the ins and outs of cost-effective T-shirt printing strategies, equipping you with the knowledge and insights needed to maximize your ROI while ensuring top-notch quality.

Introduction to T-shirt Printing for Businesses

T-shirt printing UK is a dynamic and lucrative sector within the fashion industry. It enables businesses to create custom apparel for marketing campaigns, promotional events, employee uniforms, and retail ventures. Whether you’re a startup or an established brand, harnessing the power of printing can bolster your presence in the market. However, the journey to successful printing begins with understanding the importance of cost-effective strategies.

Importance of cost-effective printing strategies

Cost-effectiveness is the cornerstone of any successful business endeavor, and printing is no exception. Efficiently managing expenses while delivering high-quality prints not only enhances profitability but also ensures sustainability. By adopting budget-savvy strategies, businesses can maintain competitive pricing, attract a wider customer base, and weather economic fluctuations.

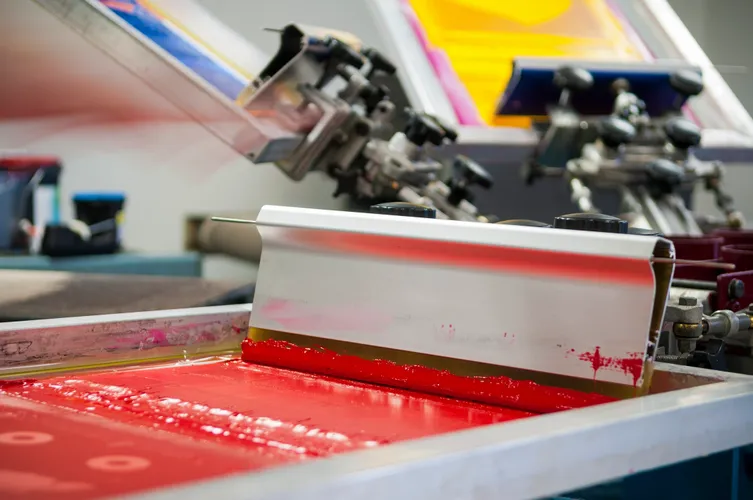

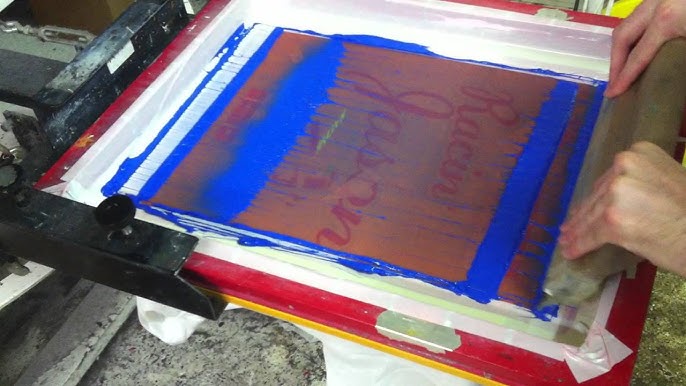

Choosing the right printing method

Selecting the appropriate printing method is a pivotal decision in the realm of cost-effective T-shirt stamping. Each method, whether it’s screen printing, direct-to-garment (DTG) printing, heat transfer, or sublimation, comes with its unique advantages and cost considerations. The right choice hinges on factors such as your production volume, design complexity, and budget constraints.

For large-scale productions with simple designs, screen stamping may offer cost-effective solutions due to its low per-unit cost. On the other hand, DTG printing shines when dealing with intricate, multicolored designs on smaller batches. Heat transfer and sublimation are ideal for full-color, all-over prints, albeit with different cost structures.

By meticulously evaluating your specific needs and financial parameters, you can make an informed decision that optimizes both quality and budget, setting the stage for successful and economical T-shirt stamping endeavors.

Sourcing budget-friendly blank T-shirts

Blank T-shirts are the canvas upon which your designs come to life. Sourcing high-quality, budget-friendly blanks is essential. Establish partnerships with reliable suppliers who offer competitive prices without compromising on fabric quality. Buying in bulk can also yield significant cost savings over time.

Design considerations for cost-efficient printing

Design plays a pivotal role in cost-effective T-shirt stamping. Simplify your designs by using fewer colors and intricate details, as this reduces ink usage and production time. Embrace vector graphics for crisp, scalable prints, and optimize the placement of your designs on the T-shirt to minimize waste.

Optimizing print file preparation

Optimizing print file preparation is a critical step in the journey of cost-effective T-shirt stamping. It involves meticulous attention to detail, ensuring that your artwork is in the correct format, resolution, and color-separated properly. By adhering to these principles, you minimize the risk of rework, save valuable production time, and reduce ink consumption. Simplifying and refining your designs for efficient printing not only enhances cost-effectiveness but also ensures that the final product meets the highest quality standards. In the realm of T-shirt stamping, a well-prepared print file is the foundation upon which successful, budget-conscious production is built, making it an indispensable skill for businesses aiming to maximize their return on investment.

Selecting economical ink and materials

Ink and materials can constitute a significant portion of your printing expenses. Explore eco-friendly and cost-effective ink options that maintain print quality while minimizing environmental impact. Likewise, choose materials such as water-based inks and organic cotton T-shirts to align with sustainability goals.

Efficient equipment and machinery selection

Investing in the right equipment and machinery is pivotal to cost-effective T-shirt stamping. While the initial outlay may seem daunting, it’s an investment that can lead to substantial long-term savings. Evaluate the durability, maintenance requirements, and efficiency of equipment to make informed decisions.

Streamlining production workflow for savings

Efficiency in your production workflow is key to minimizing operational costs. Implement lean manufacturing principles to reduce waste, optimize staff utilization, and enhance turnaround times. This not only reduces production expenses but also ensures timely order fulfillment, bolstering customer satisfaction.

Marketing and pricing strategies for profitability

Once you’ve mastered the technical aspects of T-shirt stamping, it’s time to focus on marketing and pricing strategies. Craft compelling marketing campaigns to reach your target audience effectively. Pricing should consider production costs, competitor analysis, and perceived value. Strike a balance between affordability and profitability.

Case studies of successful budget-conscious printing

To further illustrate the practical application of budget-savvy strategies, let’s explore a few case studies of businesses that have thrived in this competitive space. These real-world examples highlight the power of cost-effectiveness in achieving remarkable results.

Case Study 1: Print-on-Demand Startup

A budding print-on-demand startup recognized the importance of minimizing overhead costs. By utilizing DTG stamping, sourcing economical blanks, and adopting lean practices, they achieved a 30% reduction in production expenses within the first year. This allowed them to offer competitive pricing and attract a diverse customer base.

Case Study 2: Sustainable Apparel Brand

An eco-conscious apparel brand prioritized sustainability while staying within budget. They opted for water-based inks, organic cotton T-shirts, and heat transfer printing. By effectively communicating their commitment to eco-friendliness, they not only attracted environmentally conscious consumers but also enjoyed cost savings through bulk material purchases.

Case Study 3: Established Print Shop

An established print shop upgraded its equipment to high-efficiency screen stamping machines. They also invested in advanced print file preparation software, reducing setup times and minimizing ink wastage. These improvements led to a 25% reduction in production costs, allowing them to remain competitive in a saturated market.

Conclusion

In conclusion, mastering the art of budget-savvy T-shirt printing is a multifaceted endeavor that involves careful consideration of methods, materials, equipment, and workflow optimization. By adopting these strategies and learning from successful case studies, businesses can thrive in the T-shirt stamping industry while keeping costs in check. Ultimately, cost-effective T-shirt printing not only boosts profitability but also ensures sustainability and longevity in a highly competitive market.