Metal laser cutting machines are revolutionizing the way products are made. These machines cut metal using a focused beam of light and are used in a variety of industries, from automotive to aerospace. In this article, we will explore the workings of metal laser cutting machines, from the design process to the technology that makes them work. By the end of this guide, you will have a better understanding of how these cutting-edge machines work and what opportunities they present for your business.

What is a Metal Laser Cutting Machine?

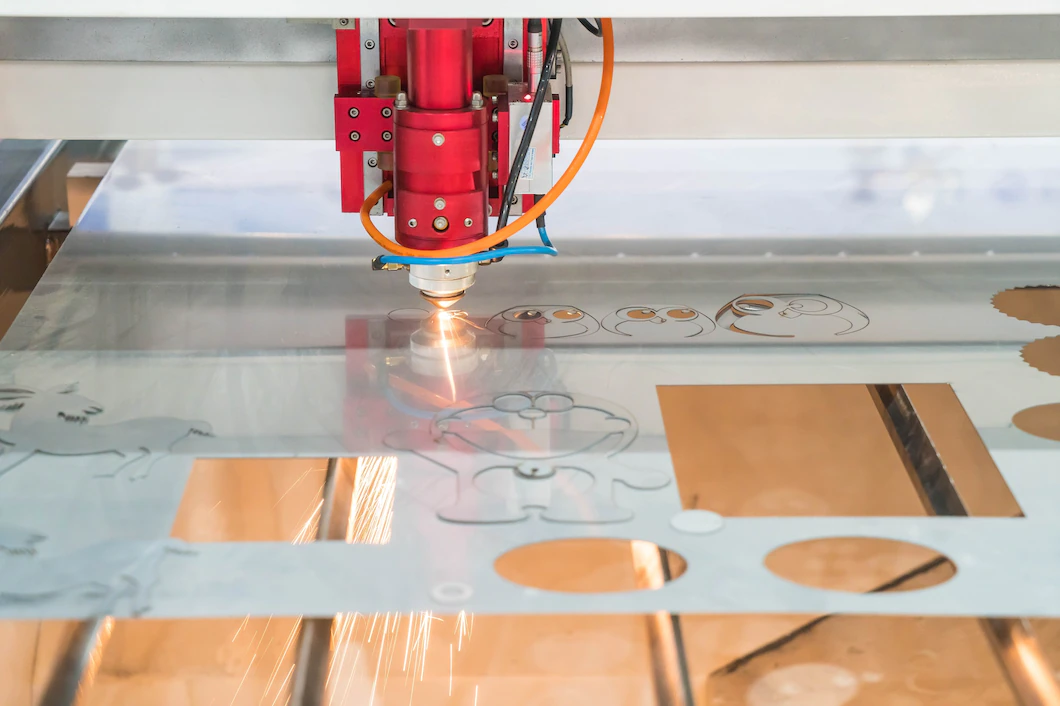

A metal laser cutting machine is a type of machine that uses a laser to cut metal sheets. It is often used in the manufacturing of metal products, such as parts for cars and airplanes.

The metal laser cutting machine uses a laser to cut the metal sheet. The laser beam cuts through the metal sheet like a knife through butter. The metal sheet can be very thin, so it is easy for the laser to cut through it.

It can be used to cut many different types of metals. It can also be used to cut different types of materials, such as wood and plastic.

How Does a Metal Laser Cutting Machine Work?

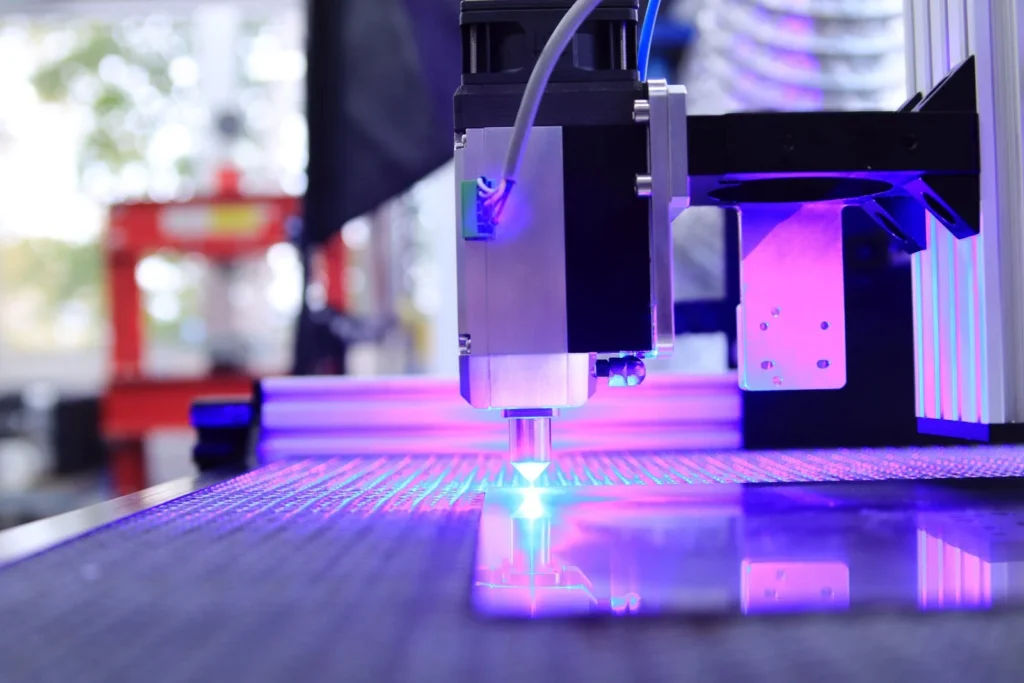

Metal processing machines are a powerful tool that can be used to create intricate cuts in metal. It works by using a laser to cut through the metal quickly and easily. This process is very accurate and can be used to create a variety of shapes and sizes.

To use a metal laser cutting machine, you first need to set up the machine with the correct software. This will allow you to design the cuts you want to make. You then need to position the metal object you want to cut on the table of the machine. The laser will then start cutting through the metal, creating the desired shape.

Metal laser cutting machines are very versatile tools and can be used for a variety of purposes. They are perfect for creating custom parts, ornaments, jewelry, and other items. If you’re looking for a powerful tool that can help you create intricate cuts in metal, a metal laser cutting machine is perfect for you.

The Advantages and Disadvantages of Metal Laser Cutting Machines

A metal laser cutting machine is a powerful tool that can be used to create intricate and precise cuts in metal. It has many advantages, including the ability to cut through tough materials with ease. However, there are also some disadvantages to metal laser cutting machines.

• One advantage of metal laser cutting machines is their precision. They can cut through even the most resistant metals with ease, which makes them perfect for creating intricate and precise cuts. This precision is also a major disadvantage for metal laser cutting machines. If the material is not cut precisely, the results can be disastrous.

• Another advantage of metal laser cutting machines is their speed. They can quickly and easily cut through metal sheets and objects. This speed is also a disadvantage because it can lead to mistakes and accidents.

If you are not careful, you could end up damaging your material or injuring yourself in an accident.

Overall, metal laser cutting machines have many advantages and few disadvantages. They are perfect for creating precise cuts in difficult materials, but they require careful attention to avoid accidents and mistakes.

Conclusion

In this article, we will be exploring how a metal laser cutting machine works and some of the benefits it has to offer. We will also take a look at some of the different types of machines available on the market today and give you an overview of what they can do. Finally, we will provide you with a 2024 guide to purchasing a metal laser cutting machine so that you can get started on your project as soon as possible!