You may be thinking about buying your first CNC machine, but before you do, there are a few things you should know. In this article, we’ll go over what CNC machines are, what they can do, and some of the things to consider before making your purchase.

Buying a CNC Machine – What to Look for?

When you’re ready to take the plunge and buy a CNC machine, there are a few things you should keep in mind to make sure you get the best machine for your needs.

• First, consider what type of material you’ll be working with most often. Different materials require different types of machines and tooling, so it’s important to know what you’ll be using your CNC for before making a purchase.

• Next, think about the size and scale of the projects you’ll be working on. A larger machine will be able to handle bigger projects, but it will also be more expensive and take up more space. If you don’t have a lot of room in your workshop, or if you plan on mostly working on smaller projects, a smaller CNC machine may be a better option for you.

• Finally, consider your budget. CNC machines can range from a few thousand dollars to tens of thousands, so it’s important to know how much you’re willing to spend before starting your search. Once you’ve considered all of these factors, you’ll be ready to start shopping for your first CNC machine!

What is the Best CNC Machine for You?

When it comes to choosing a CNC machine, there are many factors to consider. The first step is to decide what type of machine is best for your needs. There are three main types of CNC machines:

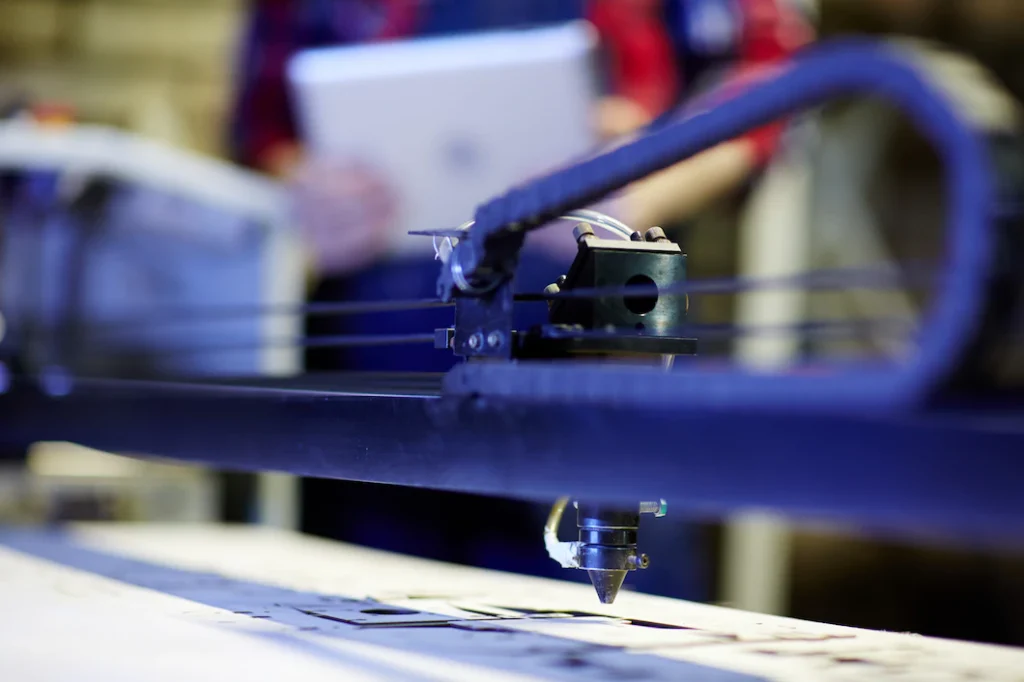

1. Milling machines: A milling machine uses rotating cutting tools to remove material from a workpiece. This is the most common type of CNC machine, and can be used for a wide variety of applications.

2. Lathes: A lathe is a type of CNC machine that turns a workpiece to create symmetrical objects such as bowls, spindles, and cylinders.

3. Plasma cutters: A plasma cutter is a type of CNC machine that uses high-powered plasma to cut through metal. This type of machine is typically used for industrial applications.

Once you have decided on the type of machine that is best for your needs, the next step is to choose a specific model. There are many different manufacturers of CNC machines, so it is important to do your research before making a purchase. Once you have selected a few potential models, be sure to read online reviews to get an idea of how satisfied other users are with the machines, or search for a CNC router for sale.

How to Get Started with Using Your New CNC Machine?

Congratulations on your new CNC machine purchase! Here are a few tips to get you started with using your machine and ensuring that you get the most out of it.

1. Read the manual! This may seem like an obvious one, but it is important to familiarize yourself with the machine and how it works before attempting to use it. The manual will also have helpful troubleshooting tips in case you run into any issues.

2. Determine what materials you will be working with. Different materials require different settings and bits, so it is important to know what you will be using the machine for before getting started.

3. Practice, practice, practice! Don’t be afraid to experiment with different settings and techniques. The more you use the machine, the more comfortable you will become with it.

4. Stay organized. Keep track of your different settings and designs so that you can replicate them in the future if needed. This will also help if you need to troubleshoot any issues that come up.

5. Ask for help if you need it. There are many online forums and groups devoted to CNC machining, so don’t hesitate to reach out for help if you need it.